Different types of fiberglass matts for different types of uses;

This combination fiberglass fabric consists of a Rovcloth base layer to which a controlled quantity of chopped fiberglass strand is deposited and chemically bonded. This process minimizes the quantity of binder insuring fast wet out and ease of handling not available with other woven/mat fiberglass products. Fabmat is thermoformable, an added benefit allowing the end user to preform the reinforcement prior to molding. This fiberglass cloth is ideal for hand lay up molding, resin infusion process, SRIM, RRIM and SCRIMP processes. FGI's proprietary sizing allows the end user complete compatibility with Polyester, Vinyl Ester, Epoxy, and Polyurethane resin systems.

What is Fab Mat?

Boatbuilders rely on AOC to deliver Altek® resins and Hydropel® high performance marine resins and gel coats that demonstrate great processability in the shop and superior performance in the water. AOC low-styrene technologies range from 100% vinyl esters to general purpose polyesters. Use the excellent blister resistance of Hydropel® high performance marine chemistry for a skin coat. Or you can go for the ultimate upgrade by specifying a Hydropel® resin for the entire laminate. Whatever your laminate schedule, give your surface the excellent protection, color and gloss of a Hydropel® high performance marine gel.

Combo Mat

All mats and clothes are sold by rolls and / or yards... Your need is our order...

This combination fiberglass fabric consists of a Rovcloth base layer to which a controlled quantity of chopped fiberglass strand is deposited and chemically bonded. This process minimizes the quantity of binder insuring fast wet out and ease of handling not available with other woven/mat fiberglass products. Fabmat is thermoformable, an added benefit allowing the end user to preform the reinforcement prior to molding. This fiberglass cloth is ideal for hand lay up molding, resin infusion process, SRIM, RRIM and SCRIMP processes. FGI's proprietary sizing allows the end user complete compatibility with Polyester, Vinyl Ester, Epoxy, and Polyurethane resin systems.

What is Combo Mat?

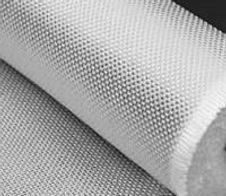

Woven cloth weaves bundles of fibers over and under one another. This is the same weave you typically see if in a table cloth, or wicker basket. Biaxial fiberglass is laid down straight, with no tight weave. On the other hand, a woven cloth relies on fibers that weave over and under each other, creating crimps that tend to be fracture points in the fibers, and in the case that they do not fracture, they will stretch far more as the loaded fibers seek straighten out. It's also import to note that in all hull laminates where biaxial is allowed, Winner uses a 100% biaxial cloth.

The straight, flat paths of fiber bundles in biaxial leads to greater strength and stiffness. By putting down straight, flat fibers, directly in line with loading forces, the fibers will resist stretching and breaking immediately and with 100% of their strength. Biaxial also tends to have a higher fiber count than woven. This has three advantages. First, more fibers means greater strength. Second, higher fiber concentration means less matrix (resin) and therefore far less brittle laminate. Third, less matrix (resin) means less weight. So in addition to the fundamental physical advantages of biaxial, we get the secondary advantages greater fiber content, greater impact resistance and lower weight.

Biaxial Cloth

Volan finish. Use this fiberglass cloth when high strength parts are desired. It is popular in the construction and repair of boats. It is also, often used in fiberglass mold making. 1-2 layers of this cloth will help protect and waterproof parts.

Volan Fiberglass

Triaxial Fiber

Triaxial fiberglass fabric is a high strength stitch bonded triaxial product. Stitch bonding mechanically combines 0° reinforcements and ± 45° reinforcements. Warp triaxial fiberglass fabrics are available with and without chopped glass strand. Combinations with glass, polyester, and other veils, along with CSM are available upon request. The resulting product is extremely conformable, offering fast wet out, and excellent processability with high dry and wet strength. Warp/Weft triaxial fabrics are ideal for hand lay up molding, resin infusion, SRIM, RRIM, and SCRIMP processes. FGI's proprietary sizing allows the end user complete compatibility, with Polyester, Vinyl Ester, Epoxy, and Polyurethane resin systems.

Rovin Fiber

Roving is a loose fabric that drapes easily, conforms to compound curves, and has a heavy weave pattern that transfers through gel coat when placed near the surface. It derives its strength from a high glass-to-resin ratio, making it ideal for contact molding or used as the last laminate layer in boats and other large structures.

Chopped strand mat can be bonded to the back for greater reinforcement. Woven roving weight is measured in ounces per square yard.

Building / Repairing Gas Tanks

Wood/Epoxy Composite Tank Guidelines

Builders have successfully constructed tanks for potable water, sewage, gray water, ballast and diesel fuel tanks and a limited number of gasoline tanks using WEST SYSTEM® Brand Epoxy since the early 1970's. The regulatory environment has evolved within the last thirty years and has placed safety restrictions on various aspects of tank building, specifically potable water and gasoline.

U. S. Coast Guard (USCG) regulations, Food and Drug Administration (FDA) regulations, American Boat & Yacht Council (ABYC) standards, and insurance restrictions should be carefully considered by anyone, professional and homebuilder alike, planning to build a composite tank. Tank construction material and construction processes have been investigated thoroughly over the years, and the lowest grief option is choosing a certified tank from a manufacturer. Certified fuel tanks have already been tested in accordance with strict fire and flame regulations, and have proven themselves in the field. Certified potable water tanks have been made to minimize or eliminate extractives.

While professional builders are bound by tough USCG regulations and ABYC standards regarding tanks, back-yard-boat builders have the option to follow or disregard them. If the back-yard-boat builder chooses to disregard the regulations and doesn't sell the boat, the builder meets the intent of the federal regulations. However, once the builder decides to sell the boat, the federal regulations become applicable and must be followed because he/she has built the boat for the purposes of sale. A good reference for individuals building boats for their own use and not for the purposes of sale is the publication, Safety Standards for Backyard Boat Builders, COMDTPUB P16761 3B. This may be obtained from USCG Headquarters or on the Internet; addresses, phone numbers, and web sites are noted in the reference section.

Before using Gougeon Brothers' products in tank construction, we advise that customers review the relevant federal, state and local safety regulations, standards, and recommended marine practices, as well as contacting their insurance carriers for restrictions. A wood/epoxy diesel fuel tank may be an uneconomical choice if insurance premiums increase or if state licensing/federal documentation problems are encountered.

General Wood/Epoxy Tank Construction

Once the epoxy leaves our shipping dock, Gougeon Brothers cannot control how the epoxy will be used. Some customers will use, and have used the epoxy to build all types of tanks. For those who decide to proceed with making tanks, here are some guidelines to help make the project as successful as possible. The key to a durable tank is a thick, well-cured epoxy coating. To minimize long-term corrosion and performance problems, we recommend that the coating be:

(1) slightly resin-rich/hardener-lean, see chart in reference section for maximum ratio

(2) well mixed, scraping sides and bottom of container

(3) elevated temperature post-cured, minimum of 120° F for 4 to 8 hours (after epoxy has cured at room temperature and is hard to the touch)

(4) thoroughly scrubbed with water and a scouring/abrasive pad, rinsed, and dried

The inside of the tank should be treated similar to the outside of a hull. We recommend a minimum of 20-mil coverage for all interior surfaces of tanks. This is similar to the coverage recommend as a "barrier coat" for the exterior of a hull, which is five to six rolled coats of epoxy. After rolling, the epoxy should be brushed out to minimize any entrapped air. Surge baffles should be installed to minimize free surface effect. The baffles should be installed with generous fillets and the fillets should get the same five to six coats of epoxy as the rest of the tank interior.

Any tank openings, such as fill, vent, inspection or clean out, should be oversized and also receive five to six coats of epoxy. We recommend that fasteners be epoxy bonded in place to secure any hardware to the tank or in the construction of the tank. Details of hardware bonding can be found in the WEST SYSTEM User Manual/Product Guide, Catalog Number 002-950 or on our web site noted in the reference section.

Carefully metered resin/hardener ratio is critical to any epoxy's performance. In all projects, with one exception, we recommend dispensing and mixing epoxy at the target ratio within our acceptable range. Tank building is the exception to the rule. When mixing epoxy for tank coatings, we recommend a resin rich/hardener lean mixture at the outer limits of the acceptable range. The table in the reference section notes the acceptable resin rich/hardener lean ratios. Please see sidebar for more in-depth discussion of our recommendation for this type of mixture.

Sidebar: Resin rich/hardener lean epoxy for tank coating

We only recommend a slightly resin rich/hardener lean mixture when dispensing and mixing epoxy for coating the insides of tanks. This is because excess resin in epoxy is less likely to adversely effect the physical properties of cured epoxy than excess hardener. When excess hardener is in the epoxy matrix, it cannot fully react with the resin and will become suspended in the mixture. Because amines (in the hardeners) are water-soluble, they can potentially leach out and cause odd tastes, contaminates in the liquid, and porosity in the epoxy film, among other performance defects. The maximum resin rich ratios noted in the reference section are at the end of acceptable ranges for WEST SYSTEM epoxy. These ratios should not be taken any farther away from the target. These maximum resin rich ratios meet specification to obtain a properly cured epoxy film and to minimize extracts leaching out of the epoxy. When using 300, 301 or 303 Mini Pumps, one way to obtain the resin rich/hardener lean ratio within the acceptable range is dispense the following:

Epoxy Combination......................Pumps Resin..........Pumps Hardener

105 Resin/205 or 206 Hardener..........6........................5

105 Resin/207 or 209 Hardener..........7........................6

Thorough mixing is difficult to achieve because the single resin or hardener components stick or cling to the sides of the container. This is readily seen when tinted epoxy is mixed together. We recommend that a double-pot mixing method be used when building or coating tanks. This is accomplished in two stages. The first stage is mixing the resin and hardener in one container, scraping the sides and bottom. Scraping is key because it incorporates the majority of the single components in the mixture. The second stage involves transferring this mixed epoxy into another clean mixing container. A new stir stick is used to mix this a second time. Any clinging material was already mixed once from the first stage and has a very low potential of being a single component.

A temporary oven or radiant heater can be used to apply an elevated temperature post-cure. A high-wattage incandescent or halogen light bulb can raise the temperature in a tank high enough to do the job. This is often the only way to do an integral tank. However, watch the fire hazard as some light bulbs can get hot enough to cause the epoxy to char or possibly ignite.

Scrubbing with water and a scouring/abrasive pad, similar to 3M's Scotch Brite® pad, removes any surface contamination, specifically any potential amine blush that may form on the surface. Amine blush is water-soluble and can be removed with tap water. The scrubbing action agitates the surface to help remove it. Solvents without high water content don't normally remove the amine blush because of its water solubility. Leave the lacquer thinner, acetone, vinegar, alcohol, and other solvents in the storage bin, use warm water if you need to deviate from the norm. Rinse again with water and dry with paper towel.

Holding Tank and Gray Water Tank Considerations

Sewage holding tanks are Type III marine sanitation devices (MSD) and are regulated under Title 33, Code of Federal Regulations Part 159 (33 CFR 159)-Marine Sanitation Devices. A Type III MSD is considered a certified tank if it: (1) is used solely for the storage of sewage and flushwater at ambient air pressure and temperature; and (2) prevents the overboard discharge of treated or untreated sewage or any waste derived from sewage (33 CFR 159.3, 159.12a, and 159.53). Type III MSDs may not be labeled. For Coast Guard Inspected vessels, the Type III MSD must also comply with 33 CFR 159.97. For the specific tank construction, make sure the internal surfaces are very smooth and that all burrs or wood splinters are removed so they don't cause anything to cling to the surfaces. This should help allow the tank to be cleaned efficiently.

Type I and Type II MSDs are more complex systems and are beyond the scope of this article, please refer to the Code of Federal Regulations for guidance.

We know of no federal regulations or other standards regarding the manufacture of gray water tanks. Use the above general guidelines for construction and you should not have any problem using WEST SYSTEM epoxy.

Potable Water Tank Considerations

We feel that the potential problems outweigh benefits and have adopted the broad policy of not recommending the epoxy for drinking water tanks because of regulatory and safety issues. To date, none of Gougeon Brothers' epoxies meet FDA regulations or any other drinking water certified approval. The major long-term concern with any plastic water tank is extractives leaching out in the water. Off-ratio, poorly cured epoxy can release extractives, as noted above. In the fabrication of water tanks and food handling equipment, the successful use of epoxy requires thorough mixing and adequate elevated temperature post-cure to assure the maximum cross-linking and cure of the polymer. These process controls are not always possible with the home-built tank. Unfortunately, neither Gougeon Brothers, Inc. nor any certification agency can verify the level of quality control exercised in the fabrication of the tank.

What about the builder who weighs the risks and decides to go ahead against our recommendation? For the homebuilder it is a personal choice. In addition to the recommendations in the general guidelines noted above, a builder may want to install an in-line filter to help remove any possible extracts and odd tastes. Professional builders should understand, again, that there are no formal approvals (awarded or pending) for Gougeon Brother's epoxy products for use in potable water tanks. Where certification is required, it is usually application specific. We have looked at the 2000 Title 21 of the Code of Federal Regulations, Part 175.300 (Food and Drug Administration, HHS) and found that the testing is specific for end-use conditions, container sizes, and frequency of use. If you have specific design/use in mind, it may be appropriate to contact the knowledgeable American or Canadian agency to identify their requirements. As with many things, the care used in the construction of the tank is the key to the overall quality.

ABYC also has a section dedicated to the general installation of potable water systems; the specific standard is H-23-Installation of Potable Water Systems for Use on Boats.

Another great agency to get information regarding potable water coatings is NSF International, The Public Health and Safety Company™. They are dedicated to testing and issuing certifications of various coatings and materials for public health and safety. You can get information off their web site to find current products that meet their various standards. Their contact information is found in the reference section below.

Fuel Tank Considerations

Fuel tank building is a controversial area. There are several USCG regulations and ABYC standards governing fuel systems. Actually, the USCG regulations are only applicable for gasoline fuel systems, not diesel fuel. Because of gasoline's lower flash point, higher volatility and combustibility, gasoline systems are more regulated than diesel fuel systems. These regulations are very specific and contain stringent requirements for the fill systems, vents, installation, testing and labeling.

The USCG regulatory information can be obtained at USCG Headquarters and at each Coast Guard District's Boating Safety Division, all of these contacts are noted in the reference section, too. The guiding regulations for gasoline tanks in recreational boating are contained in Title 33 of the Code of Federal Regulations, Part 183.501 through 183.590. The regulations may be found on the World Wide Web at no charge or may be obtained for a nominal fee from the Government Printing Office. These sources are found in the reference section. The ABYC standards for gasoline systems are found in Standard H-24-Gasoline Fuel Systems and H-25-Portable Gasoline Fuel Systems.

Although the USCG doesn't publish any regulations for recreational boat diesel fuel systems, ABYC publishes a written a standard, Standard H-33-Diesel Fuel Systems. It would behoove customers to obtain a copy to ensure all safety precautions and recommended practices are followed.

Conclusion

All types and variations of tanks have been successfully constructed with WEST SYSTEM Brand epoxy and used in the field with great results. However, Gougeon Brothers does not condone or recommend that certain tanks be built because of various issues noted above. In our testing, various epoxy combinations have proven to be resistant to various liquids, including gasoline, diesel fuel, motor oil, potable water, sea water, sewage, gray water, etc. Regarding gasoline specifically, some epoxy combinations are more resistant than others are. With the increasing use of alcohol and other high-tech additives, we are unsure how the epoxy will resist them in the future. We do know that many types of alcohol vigorously attack epoxy, we can only conclude that gasoline with a higher percentage of alcohol may not have favorable results in long-term use.

Before building gasoline tanks and potable water tanks, do your homework and take into consideration the information above. The resources and various agencies noted below should help you make informed decisions regarding tanks and whether or not you should build your own. The final decision to build or not to build rests on the builder, we hope this document helps the builder make sound, educated decisions. As always, please contact the Technical Staff if specific questions arise.

References and Resources:

Safety Standards for

Backyard Boat Builders,

COMDTPUB P16761 3B

Commandant (G-OPB-3),

US Coast Guard,

2100 Second Street, SW,

Washington DC, 20593-0001,

(202) 267-0984

USCG Infoline: (800) 368-5647

http://www.uscg.mil/d8/mso/louisvill...bp16761_3b.pdf

Recreational Boating Safety,

U. S. Coast Guard Headquarters:

Commandant (G-OPB),

US Coast Guard,

2100 Second Street, SW,

Washington DC, 20593-0001,

(202) 267-0984

USCG Infoline: (800) 368-5647

www.USCGBoating.org

Code of Federal Regulations:

Government Printing Office

Credit Card: (202) 512-1800, M-F, 8-4

Fax Order: (202) 512-2233 24 hours

Payment by check:

Superintendent of Documents

Attn: New Orders

P. O. Box 371954

Pittsburgh, PA 15250-7954

Customer Service: (202) 512-1803

Free on World Wide Web

Fuel Tanks: http://www.access.gpo.gov/nara/cfr/w...cfr183_00.html

Marine Sanitation Devices:

http://www.access.gpo.gov/nara/cfr/w...cfr159_00.html

Fuel tanks for USCG Inspected Vessels (<100 GT)

http://www.access.gpo.gov/nara/cfr/w...cfr182_00.html

Food and Drug Administration:

5600 Fishers Lane

Rockville MD 20857-0001

http://www.access.gpo.gov/nara/cfr/w...cfr175_00.html

NSF International

PO Box 130140

789 N. Dixboro Road

Ann Arbor, MI 48113-0140, USA

www.nsf.org

Tel: (734) 769-8010

Toll Free (USA): (800)-NSF-MARK

Fax: 734-769-0109

American Boat & Yacht Council

3069 Solomons Island Road

Edgewater, MD 21037-1416

Tel: (410) 956-1050

Fax: (410) 956-2737

info@abycinc.org

www.abycinc.org

U.S Coast Guard Districts,

Boating Safety Divisions

COMMANDER (opb)

First Coast Guard District

Capt. John Foster Williams Bldg.

408 Atlantic Avenue

Boston, MA 02110-3350

Tel: (617) 223-8480

COMMANDER (opb)

Fifth Coast Guard District

Federal Bldg.

431 Crawford Street

Portsmouth, VA 23704-5004

Tel: (757) 398-6000

COMMANDER (opb)

Seventh Coast Guard District

Brickell Plaza Federal Bldg.

909 SE First Ave.

Miami, FL 33131-3050

Tel: (305) 536-5654

COMMANDER (opb)

Eighth Coast Guard District

Hale Boggs Federal Building

501 Magazine Street

New Orleans, LA 70130-3396

Tel: (504) 589-6298

COMMANDER (opb)

Ninth Coast Guard District

1240 East 9th St

Cleveland, OH 44199-2060

Tel: (216) 902-6001

COMMANDER (opb)

Eleventh Coast Guard District

Coast Guard Island

Alameda, CA 94501-5100

Tel: (510) 437-3324

COMMANDER (opb)

Thirteenth Coast Guard District

Jackson Federal Bldg

915 Second Ave

Seattle, WA 98174-1067

Tel: (206) 220-7237

COMMANDER (opb)

Fourteenth Coast Guard District

Prince Kalanianaole Federal Bldg.

300 Ala Moana Blvd., 9th Floor

Honolulu, HI 96850-4982

Tel: (808) 541-2121

COMMANDER (opb)

Seventeenth Coast Guard District

P.O. Box 25517

Juneau, AK 99802-5517

Tel: (907) 463-2065

Gougeon Brothers Inc.

100 Patterson Ave., PO Box 908

Bay City, MI 48707-0908 U.S.A.

Tel: 989-684-7286

fax: 989-684-1287

URL: www.gougeon.com

www.westsystem.com

E-mail: TS@gougeon.com